Screen Print Clean Room :All screen Printing at Bolin is done is a ISO Class 7 clean room.24,000 cubic feet of air move through the HEPA filters each minute .This clean environment increases yields and eliminates potential contamination that can cause reliability problems.

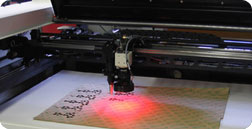

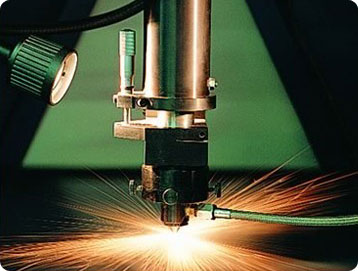

Laser Cutting:Laser cutting allows us to produce precise parts without tooling ,cutting at speeds of up to1000 inches per minute .Laser cutting is particularly well suited for prototypes and short runs.

Membrane Switch Assembly: All membrane switches are assembled in our assembly clean room, which eliminates potential contamination, increases yields and improves switch reliability .Currently our assembly clean room is staffed with over sixty trained professionals.

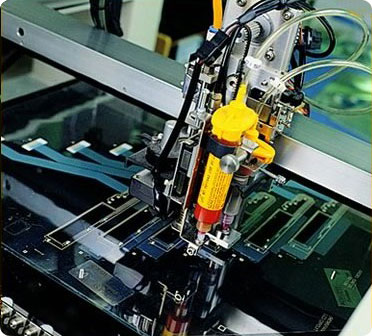

LED Assembly : The assembly of surface mounted LED’s that are embedded in to a membrane switch is automated with our pick and place equipment .Automation is cost effective and ensures repeatability.